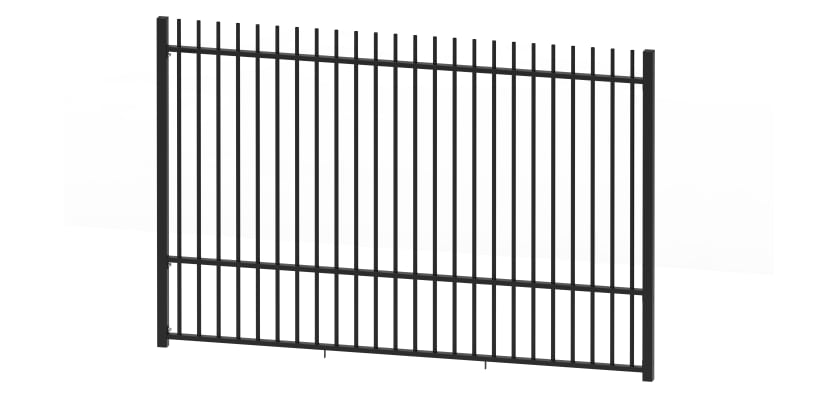

2.0m High EnviroRail® Vertical Bar Round Railing Kit

| Installed Height | 2000mm [Above Ground Incl. Clearance] |

| Total Post Length | [Bolt down: 2000mm] [Dig In: 2600mm] |

| Panel Width | 2900mm |

| Total Wdith | 2960mm from post centre to post centre |

| Weight | [Bolt down: 64.5kg] [Dig In: 66.5kg] |

| Box Section of Posts | 60mm x 60mm |

| Base Plate Size | 150mm x 150mm |

| Thickness of Railing Bars | 25.4mm |

| Distance Between Railing Bars | 120mm from bar centre to bar centre |

| Rail Style | Vertical Bar - Hollow Tubular |

| Post Type | Dig In, Bolt Down |

| Material | Pre-Galvanised Steel |

| Finish | Polyester Powder Coated (PPC) |

| PPC Colours | Green, Black, Blue, Red, Grey, Yellow |

| Name | Quantity |

|---|---|

| EnviroRail® Vertical Bar Railing Panels | 1 |

| Railing Posts | 1 |

| Twist Cleats | 6 |

| M10 x 80mm Bolts | 3 |

| M10 Shear Nuts | 3 |

| Support Legs | 2 |

| Ribbed Post Insert | 1 |

2.0m High EnviroRail® Vertical Bar Round Railing Kit

Standing at 2.0m high, these EnviroRail® provide an excellent deterrent to would be intruders whilst also maintaining a stylised and great looking perimeter. These round vertical bar railings are suitable for use in creating boundaries in a wide range of public or private outdoor spaces such as parks and gardens. Each bay has been constructed to meet our exceedingly high standards from high quality steel, ensuring that they will remain strong and looking good for many years to come. Each of the 2.0m High EnviroRail® Vertical Bar Round Railing Kits comes with a panel, post and the fixings required to attach the panel to the post.

Visually, the 2.0m EnviroRail® look very similar to standard vertical bar railings. The key difference lies in the method of manufacture.

Standard vertical bar railing systems may require a lot of welding in order to join the individual components together, which as a process can be very energy and resource intensive. In order to reduce the amount of welding required, therefore reducing the amount of energy and resources required, the EnviroRail® systems use a revolutionary new construction technique.

This innovative reduced weld construction process uses a series of custom formed and laser cut components which have been specially designed to interlock and create an incredibly strong bond when pressed together.

Each EnviroRail® kit is comprised of pre-galvanised steel hollow tubular sections. These hollow tubes provide an incredibly high level of strength whilst helping to keep the weight to a minimum, making handling, transport and installation much easier.

EnviroRail® Vertical Bar Railing kits are supplied with the option of either dig in or bolt down posts, in order to allow for installation on a variety of different ground types.

Dig in posts – The dig in posts have been created to allow for installation on softer forms of ground where it is possible for holes to be easily dug. The dig in posts are supplied in a longer length than the height of the railings themselves, which allows for a portion of the post to be placed into the hole, where it is then securely held in position with the use of post mix

Bolt down posts – The bolt down post has been designed for use on harder ground surfaces such as concrete, where it may not be possible to dig holes. These posts are supplied with base plates which allow for ground anchor bolts to be used to secure the post in place.

Each 2.0m high railing kit includes:

The 2.0m High EnviroRail® Vertical Bar Railing kits are supplied with the following components:

- 1 x EnviroRail® Vertical Bar Railing Panel

- 1 x EnviroRail® Railing Post

- 6 x Twist Cleats

- 3 x M10 x 80mm Bolts

- 3 x M10 Shear Nuts

- 2 x Support Legs

- 1 x Ribbed Post Insert

As each of these railing kits is supplied with one post, an additional post will be required to finish each straight line run of railings.

Benefits and features

- Reduced weld construction – This revolutionary and environmentally friendly form of manufacture reduces the amount of energy and resources required to create a railing bay.

- Made to last – Each bay has been constructed to out exceedingly high standards from steel, these railings will remain strong, sturdy and looking good for many years to come.

- Hollow tube construction providing an excellent level of strength whilst helping to keep weight to a minimum.

- Suitable for installation on a range of ground types – These kits are available with either dig in or bolt down posts

- Customise with a PPC finish – The EnviroRail® Vertical Bar Railing bays are finished with a high quality Polyester Powder Coating (PPC). These coatings are available in a wide range of RAL colours to create a fantastic looking perimeter system, as well as providing a layer of protection against weathering and rust.

Customise your EnviroRail® Railing Kits

As standard, each of the 2.0m High EnviroRail® Vertical Bar Railing kits are finished with a high-quality Polyester Powder Coating (PPC). These professionally applied coatings leave the railings with a smooth finish and are available in a wide range of RAL colours, allowing for the creation of a bright, colourful and aesthetically pleasing perimeter system. As well as providing some colour to your railing perimeter, these Polyester Powder Coatings provide an additional function of creating a protective barrier which protects the steel from the damaging effects of rust and weathering.

In the unfortunate event of the Polyester Powder Coatings becoming damaged, either through accidental damage, or through acts of vandalism, it is possible to restore these coatings quickly and simply with the use of touch up spray cans. These spray cans provide a smooth and even finish which restores the powder coatings, keeping them looking great and restoring the protective barrier to the steel.

How to step your panel

Step One: Drill a 6mm pilot hole in the desired location for the new cleat; this is dictated by the gradient.

Step Two: Open the hole to a 12mm hole size to take the M10 bolts (as listed in the step below).

Step Three: Touch up and spray the hole, if required.

Step Four: Attach the cleat using the M10 x 70mm Square Cup Head Bolt and Shear Nut (for 0.9m to 1.2m height system) or M10 x 80mm Square Cup Head Bolt and Shear Nut (1.5m to 2.4m height systems).

Step Five: Attach the railing panel as per standard installation guidance.

Note: Please ensure the spacing relationships are followed according to the existing hole centres on the posts.

Take a look at the rest of our EnviroRail® railing systems

As well as the Vertical Bar Railing systems, be sure to also take a look at the other railing systems that are available in the EnviroRail® range. Bow Top railings provide a more curved stylised finish to your railing system, or Play Sec Bow Top Railings which are an ideal solution for creating perimeters around children’s play areas or parks.

Contact us

Should you have any questions regarding these EnviroRail® railing systems, or any of the other fencing and railing solutions that we have, please don’t hesitate to get in touch. We can be reached via phone on 01283 512 111, by email at sales@firstfence.co.uk or it is also possible to speak to one of our helpful and friendly sales team through our online chat system.