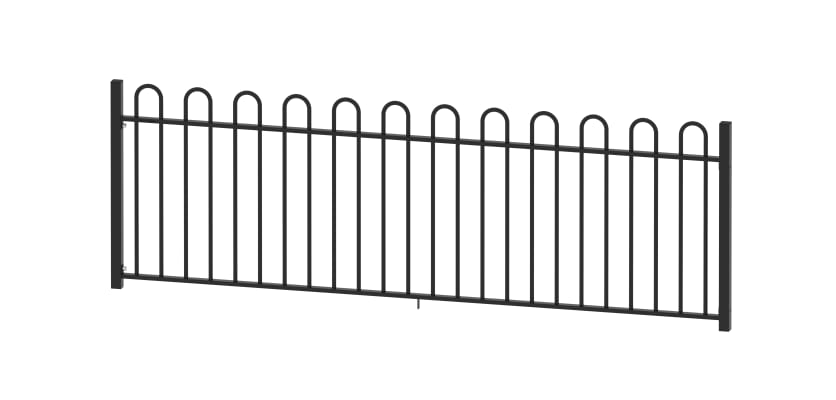

1.0m High EnviroRail® Standard Bow Top Railing Kit

| Installed Height | 1000mm [Above Ground Incl. Clearance] |

| Total Post Length | [Bolt down: 1000mm] [Dig In: 1500mm] |

| Panel Width | 2900mm |

| Total Width | 2950mm from post centre to post centre |

| Weight | [Bolt down: 24.6kg] [Dig In: 24.8kg] |

| Box Section of Posts | 50mm x 50mm |

| Base Plate Size | 150mm x 150mm |

| Thickness of Railing Bars | 20mm |

| Distance Between Railing Bars | 120mm from bar centre to bar centre |

| Rail Style | Bow Top - Hollow Tubular |

| Post Type | Dig In, Bolt Down |

| Material | Pre-Galvanised Steel |

| Finish | Polyester Powder Coated (PPC) |

| PPC Colours | Green, Black, Blue, Red, Grey, Yellow |

| Name | Quantity |

|---|---|

| EnviroRail® Bow Top Railing Panels | 1 |

| Railing Posts | 1 |

| Twist Cleats | 4 |

| M10 x 70mm Bolts | 2 |

| M10 Shear Nuts | 2 |

| Support Legs | 1 |

| Ribbed Post Insert | 1 |

1.0m High EnviroRail® Standard Bow Top Railing Kit

These 1.0m High EnviroRail® Standard Bow Top Railings are a stylish, strong and cost-effective railing system which can create fantastic looking perimeters in a wide range of outdoor locations for a variety of applications. The bow top design helps to eliminate any points on the these railing bays and makes them suitable for use in areas where there may be children playing such as parks and schools. Each of these bays has been made to our exceedingly high standards. To protect the steel and allowing for the creation of a visually appealing perimeter, each of these railing bays has been finished with a professionally applied Polyester Powder Coating (PPC) in a range of RAL colours. To enable quick and easy installation, the 1.0m High EnviroRail® Standard Bow Top Railing Kits includes a panel, post and the fixings required to attach the panel to the post.

Whilst EnviroRail® Standard Bow Top Railings may look similar to a standard bay of bow top railings, the differences lie in the manufacturing process. The EnviroRail® railing systems have been constructed using a new environmentally friendly technique which greatly reduces the amount of welding required. Standard bow top railing systems may require many individual welds to join the components together. This can be a very resource and energy intensive process which has negative effects on the environment.

EnviroRail® railing systems reduced weld construction uses a series of bespoke formed and laser cut components. These components have all been specially designed so that they interlock and, once pressed together, form an incredibly secure bond which provide these railings with a high level of strength and stability. This system is more energy and resource efficient, and whilst there is still some welding joins required, there are considerably less than standard railing bays.

Each EnviroRail® kit is comprised of pre-galvanised steel hollow tubular sections. These hollow tubes provide an incredibly high level of strength whilst helping to keep the weight to a minimum, making handling, transport and installation much easier.

So that these bow top railings can be installed in a wide variety of locations, these EnviroRail® Standard Bow Top Railings are supplied with either dig in or bolt down posts.

Dig in posts – The dig in posts have been created to allow these railings to be installed in locations where there are soft ground types, allowing for holes to be dug easily. These posts are longer than their bolt down variants allowing for part of the post to be placed in the ground and held in place with the use of post mix.

Bolt down posts – Bolt down posts are an effective solution for installing these railings on hard ground surfaces where it may not be possible to dig holes. These posts come with base plates pre-attached, allowing for ground anchor bolts to be used to secure the posts in place.

Each kit contains:

Each of the 1.0m High EnviroRail® Standard Bow Top Railings include the following components:

- 1 x EnviroRail® Bow Top Railing Panel

- 1 x EnviroRail® Railing Post

- 4 x Twist Cleats

- 2 x M10 x 70mm Bolts

- 2 x M10 Shear Nuts

- 1 x Support Leg

- 1 x Ribbed Post Insert

Each of these kits is supplied with one post, so an additional end post will be required in order to finish a line of bow top railings.

Features and Benefits

- Stylish bow top design – These EnviroRail® bow top railings are sleek and stylish, whilst also removing pointed ends from the top of the railing bay.

- Reduced weld construction – This revolutionary reduced weld system greatly reduces the amount of energy and resources required to produce each bay.

- Made to last – Consisting of a robust construction, made to our highest standards and finished with a professionally applied PPC finish, these railings are made to last and look great for years.

- Hollow tube construction providing an excellent level of strength whilst helping to keep weight to a minimum.

- Suitable for installation on a range of ground types with both dig in and bolt down posts available

- High quality PPC finish – Each of these railing kits has been finished with a professionally applied Polyester Powder Coating (PPC) finish. These are available in a range of RAL colours, providing a layer of protection to the steel as well as creating an aesthetically pleasing perimeter.

Customise your EnviroRail® Bow Top Railings

As standard, each of these 1.0m EnviroRail® Standard Bow Top Railings are finished with a high-quality Polyester Powder Coating (PPC). These coatings are available in a wide range of RAL colours, which can be used to create a fantastic aesthetically pleasing perimeter or coloured to match an existing organisations colours. These coatings also provide an additional function by creating a protective barrier, helping to prevent the formation of corrosion on the steel.

In the unfortunate event of these powder coatings becoming damaged, either through accidental damage or through intentional vandalism, it is possible to restore the protective barriers these coatings provide as well as restoring their visual appeal with the use of a touch up spray can

Be sure to take a look at the rest of our EnviroRail® railing systems

As well as these 1.0m High EnviroRail® Bow Top Railings, there are more heights available, if you require a different style of railing to create your perimeter systems, there are also EnviroRail® Vertical Bar Round Railings, or if you require a child friendly alternative for schools or play areas, the EnviroRail® Play Sec Bow Top Railings are an excellent option.

Contact us

If you should have any questions regarding these railings, or any of our other perimeter security solutions, then please get in touch. Our friendly and helpful team can be contacted via phone on 01283 512 111, by email at sales@firstfence.co.uk or through our online live chat system.